Understanding Cranes: A Comprehensive Guide for All Types of Cranes

Cranes are essential machinery in various industries, particularly in manufacturing and construction. They play a critical role in lifting, transporting, and arranging heavy objects and machinery. This guide will explore how cranes work, the different types available, and their specific applications, focusing on manufacturers of all types of cranes, including the cranes exclusively manufactured by Shri Bhagwati Machines Pvt. Ltd.

How Does Cranes Work?

Cranes operate on fundamental principles that allow them to lift heavy loads with ease. Here’s a breakdown of the basic operational principles:

1. Mechanical Advantage

Cranes utilize mechanical components such as levers and pulleys to gain a mechanical advantage. This reduces the amount of effort required to lift heavy objects, making it easier for operators to manage large loads.

2. Distribution of Loads

Cranes are designed to distribute weight evenly across their structure. This distribution minimizes structural stress and enhances stability during lifting operations. Key components such as the base, boom, and counterweights work together to maintain balance. .

3. Control Systems

Modern cranes are equipped with sophisticated control systems that allow operators to maneuver loads precisely. These systems may include levers, joysticks, or remote controls, enabling smooth operation even in complex environments.

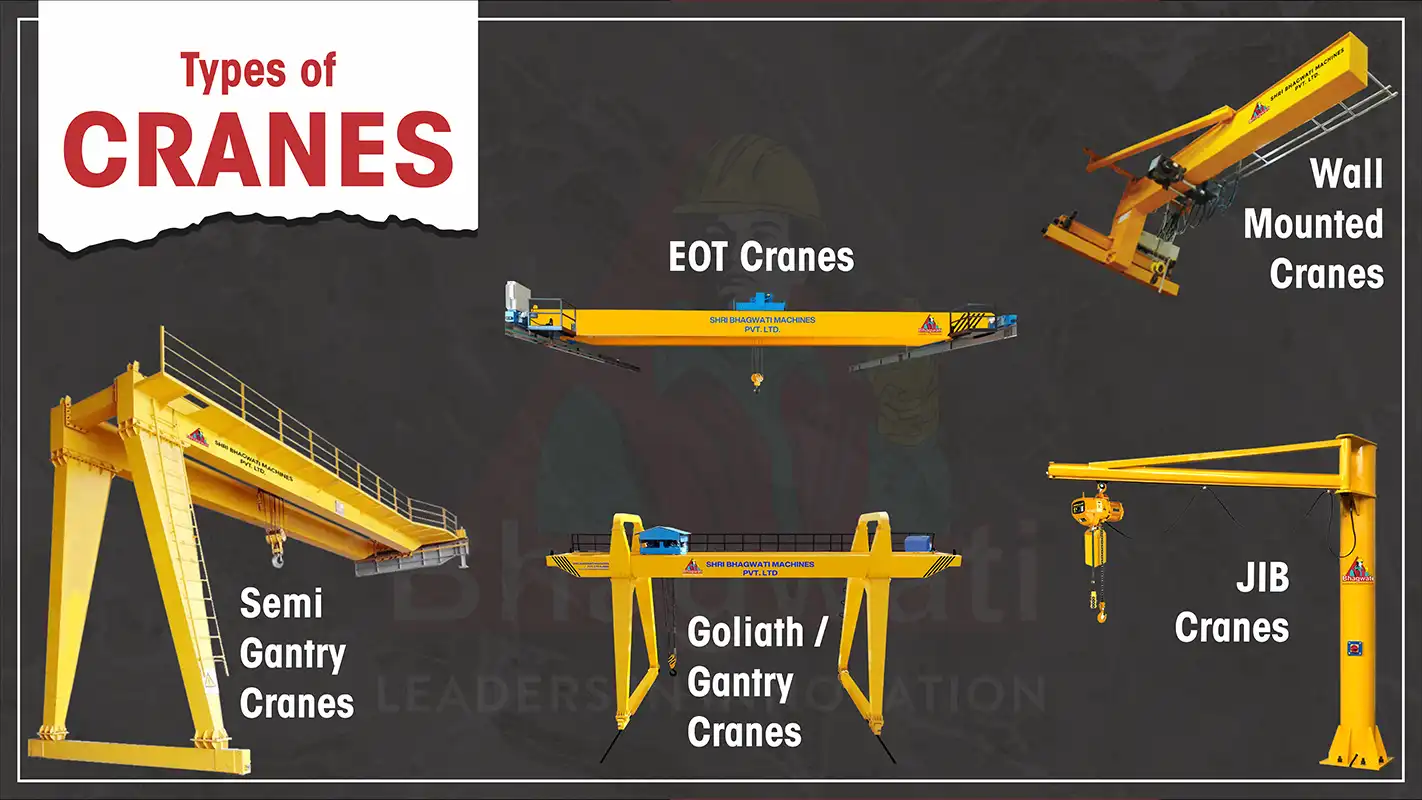

Types of Cranes and Their Purposes

Cranes come in various types, each designed for specific tasks within manufacturing and construction. Here are some common types:

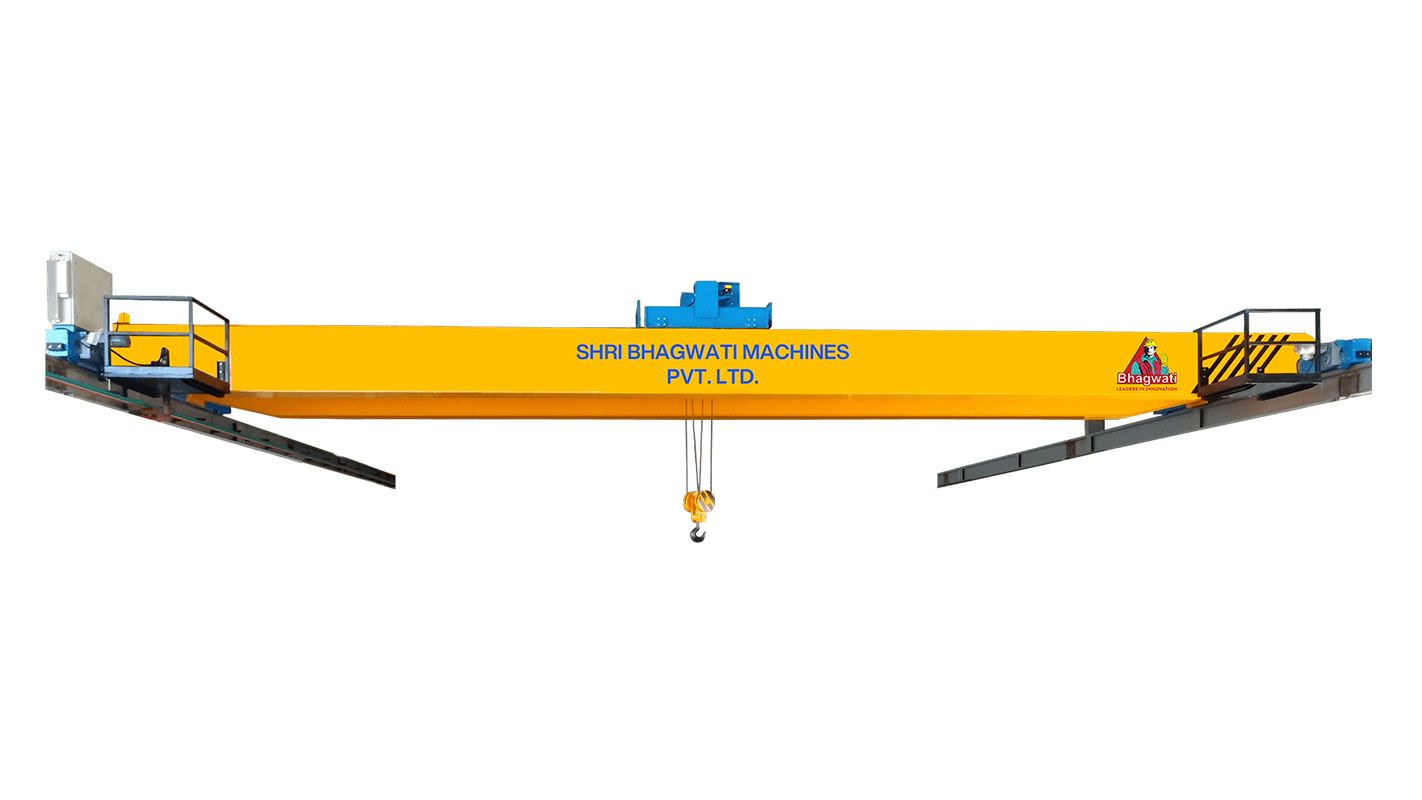

1. EOT Cranes

SBMPL is a prominent manufacturer of Electric Overhead Traveling (EOT) cranes, known for their exceptional quality and reliability. EOT cranes are essential in various industrial applications, providing efficient solutions for lifting and transporting heavy loads with ease. Designed to operate on a fixed track, these cranes feature a robust construction that ensures stability and safety during operation. The EOT cranes manufactured by Shri Bhagwati Machines are equipped with advanced control systems, allowing for precise maneuverability and enhanced operational efficiency. Their design maximizes workspace utilization, making them ideal for factories, warehouses, and construction sites. With a commitment to excellence, SBMPL has established itself as a trusted name in the crane industry, delivering high-performance EOT cranes tailored to meet the diverse needs of clients across

2. Wall Mounted Cranes

Wall-mounted cranes are specially designed to optimize space and enhance efficiency in various industrial settings. Shri Bhagwati Machines Pvt. Ltd. specializes in manufacturing high-quality wall-mounted cranes. These cranes are ideal for environments where floor space is limited, as they utilize overhead areas effectively, allowing for the lifting and moving of loads without occupying valuable ground space.

3. JIB Cranes

Jib cranes are versatile lifting solutions that feature a horizontal arm (jib) mounted on a vertical mast, allowing for flexible load handling within a defined radius. We are a leading manufacturer of high-quality jib cranes, designed to enhance efficiency and productivity in various industrial applications.

4. Gantry/Goliath Cranes

Gantry and Goliath cranes are, designed to meet the diverse needs of various industries. These cranes are essential for lifting and transporting heavy loads, making them invaluable in manufacturing, construction, and logistics. Shri Bhagwati Machines Pvt. Ltd. is a premier manufacturer renowned for producing high-quality Gantry and Goliath Cranes.

4. Semi Gantry Cranes

As a prominent manufacturer of semi-gantry cranes, Shri Bhagwati Machines Pvt. Ltd. offers innovative lifting solutions tailored for diverse industrial applications. These cranes boast a distinctive design, with one leg gliding smoothly on a track while the other is anchored to a wall or column. This unique configuration provides exceptional versatility, making them ideal for maneuvering in tight spaces where traditional gantry cranes might struggle.

5. Additional Crane Types

- Mobile Cranes: These cranes offer mobility on job sites and can be driven on highways.

- Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

- Rough Terrain Cranes: Designed for off-road use with enhanced stability on uneven surfaces.

- Crawler Cranes: Feature tracks for mobility and can lift extremely heavy loads.

- Floating Cranes: Used in maritime applications for loading and unloading cargo from ships.

Operational Procedures for Planning and Setup

- Preoperative Planning: Engineers and operators assess the site, calculate load weights, and plan the lifting procedure to ensure efficiency and safety.

- Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

- Lifting Procedure: Operators use control systems to raise the load while counterweights help maintain balance

- Weight Shifting: Once lifted, the operator carefully moves the load horizontally using the boom or gantry system while ensuring precise synchronization to avoid obstructions.

- Positioning: The operator gently lowers the load into place, often guided by signals from ground crew members to ensure accuracy.

Conclusion

Understanding the various types of cranes available is crucial for manufacturers looking to optimize their operations in the construction and manufacturing sectors. Companies like Shri Bhagwati Machines Pvt. Ltd play a vital role in providing high-quality crane solutions tailored to meet industry needs. By leveraging advanced technology and adhering to safety standards, crane manufacturers can enhance productivity while ensuring safe operations on job sites. Whether you require overhead cranes for your factory or mobile cranes for construction projects, selecting the right type of crane is essential for achieving operational excellence.

Frequently Asked Questions regarding types of manufacturing and construction cranes

- How do cranes work?

Cranes used in manufacturing and construction are essential for lifting, transporting, and arranging large objects and machinery. - What is the Basic Crane Operation Principles Mechanical Advantage ?

Cranes have an edge when lifting large objects because they use mechanical components like hydraulic cylinders, levers, and pulleys. This lowers the amount of work required to move objects. - How cranes helps in Distribution of Loads ?

Cranes disperse weight uniformly, reducing structural stress and guaranteeing stability. To balance loads, the base, boom, and counterweights cooperate. - What are System Of Control in Cranes ?

Control systems installed on cranes enable operators to precisely move loads. Levers, joysticks and occasionally remote controllers that are manipulated by hand fall under this category. - What are Overhead Cranes ?

These tracks-based cranes are commonly observed in production facilities and have the ability to lift and transport objects within a predetermined region. They are very handy when transferring large items between warehouses or assembly lines. - What are wall-mounted Cranes ?

?

Wall-mounted cranes serve a specific and valuable purpose in the manufacturing and construction industries. Here’s a detailed overview of their functions and benefits: Wall-mounted cranes allow for lifting and moving loads in areas where floor space is limited. They utilize overhead space, leaving the floor clear for other activities.Their installation against walls helps free up valuable floor space, making them ideal for smaller workshops or factories. - What are JIB Cranes ?

Jib cranes are adaptable lifting tools that are frequently utilized in a variety of sectors, such as building, manufacturing, and warehousing. Jib cranes can raise and move big loads both horizontally and vertically, which makes them appropriate for a variety of tasks, including handling commodities and moving industrial parts. - What are the Operating Procedures for Planning and Setup in Manufacturing and Construction ?

Engineers and operators arrange the lifting procedure, calculate load weights, and evaluate the site before starting up. Efficiency and safety are guaranteed by a proper setup.