What Are Multicutter Machines

Granite multi-cutter machines are essential tools in the stone-cutting industry, allowing for precise and efficient cutting of granite materials. These machines are equipped with multiple blades that can make several cuts simultaneously, increasing productivity and reducing labor costs. The use of multi-cutter machines has revolutionized the way stone cutting is done, making it faster, more accurate, and more cost-effective.

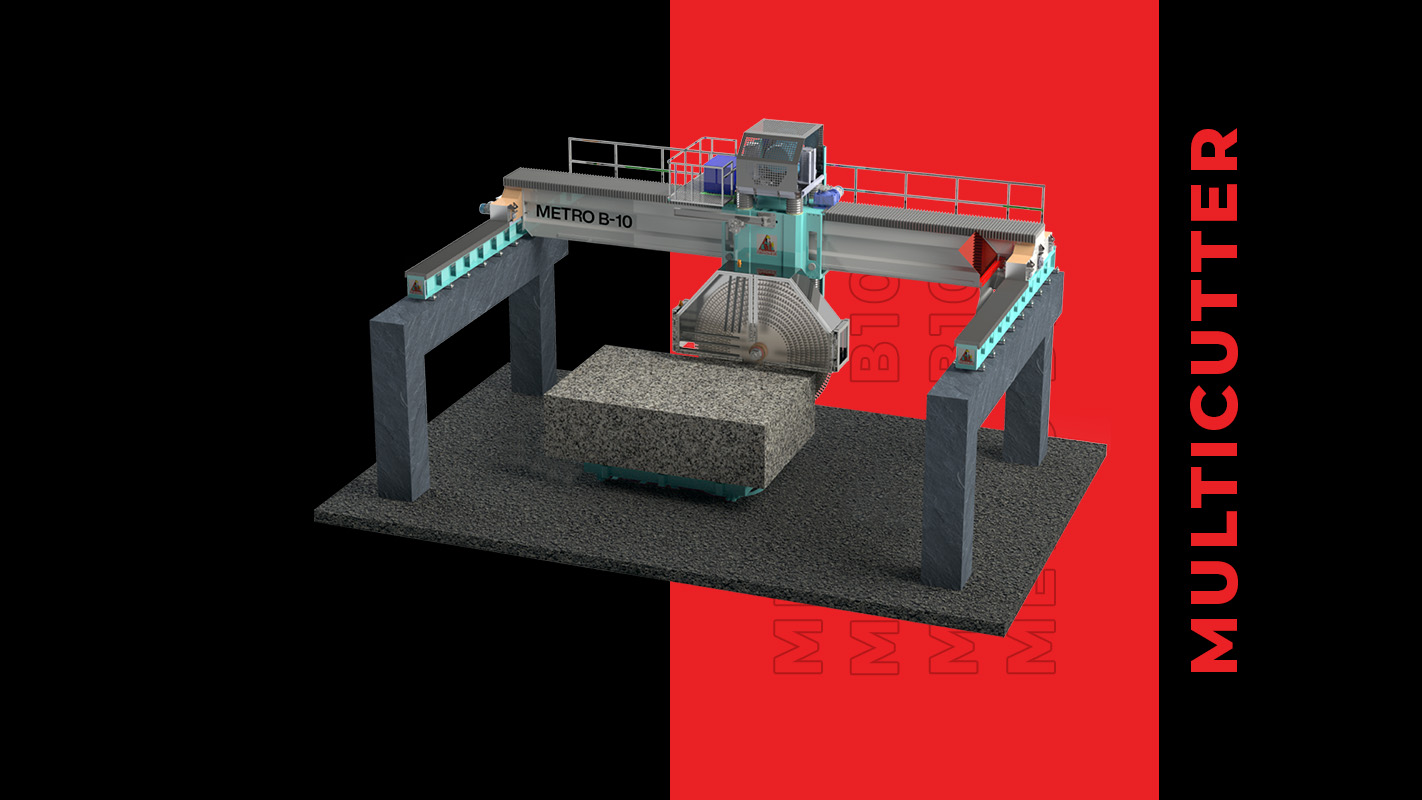

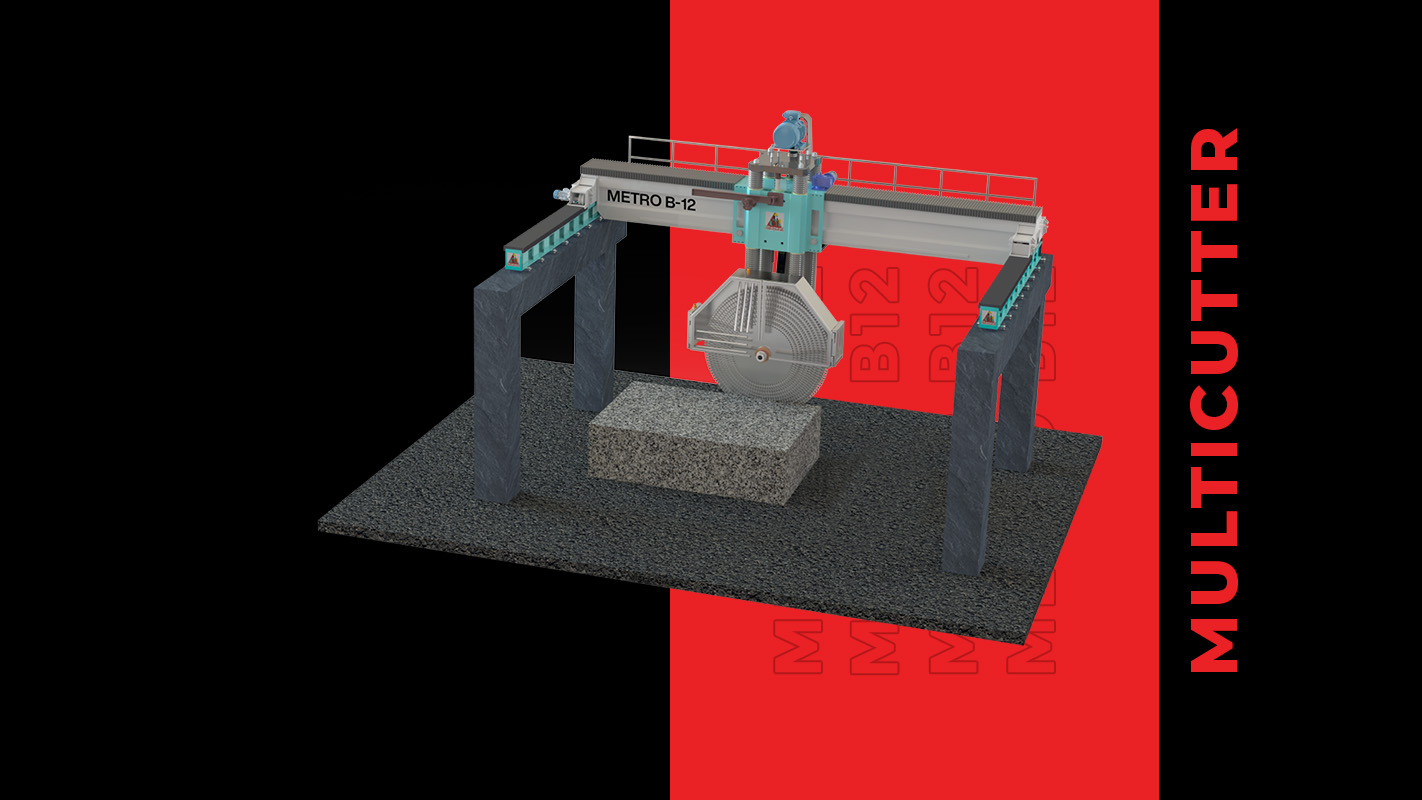

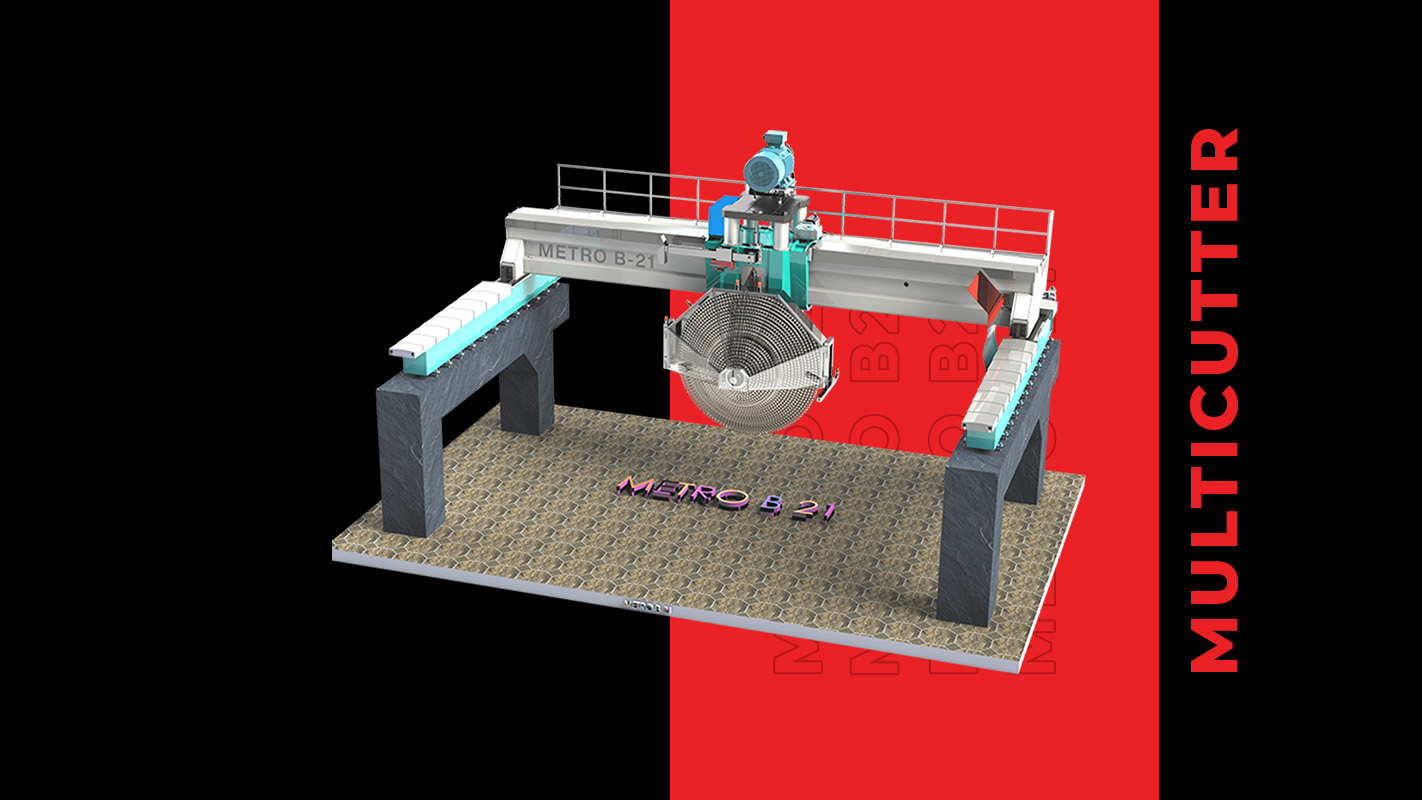

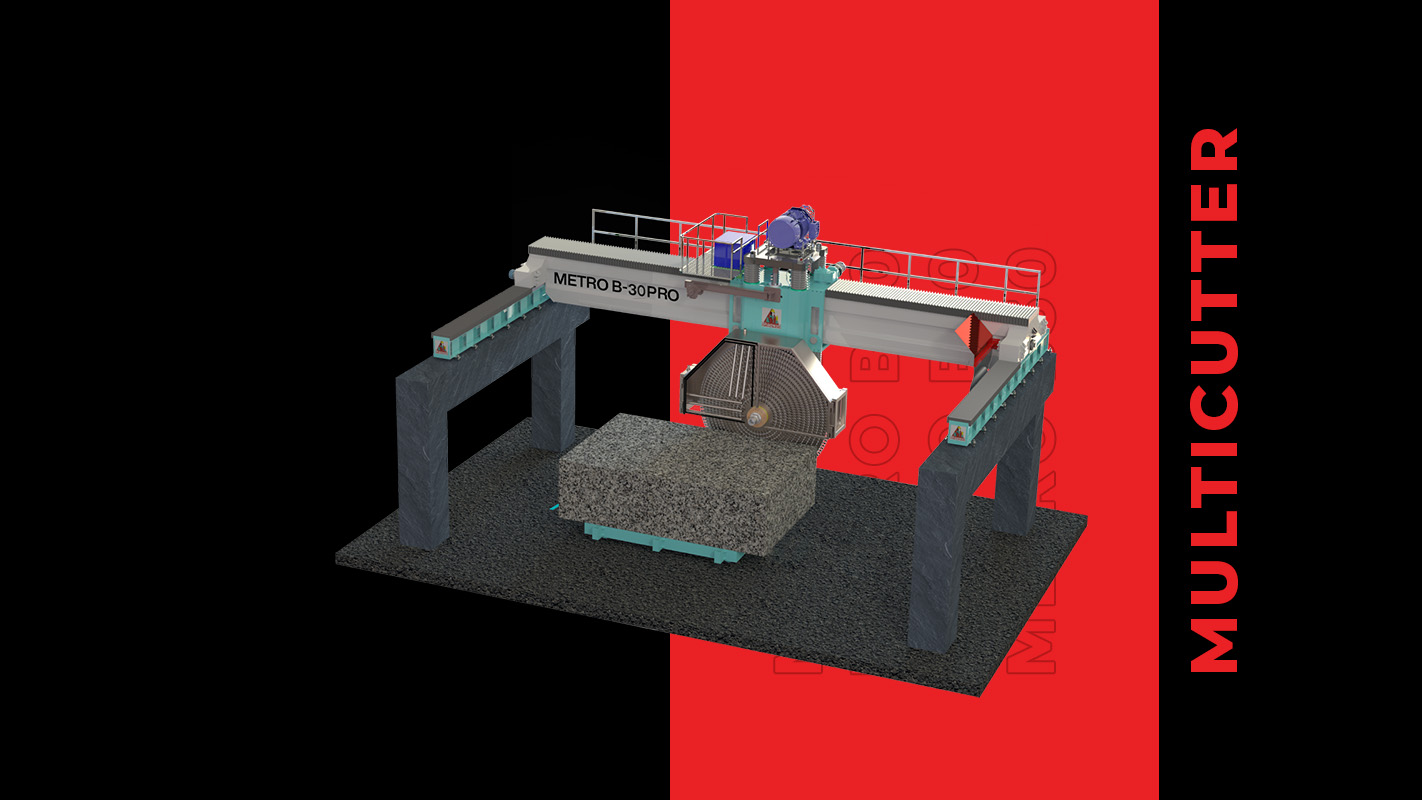

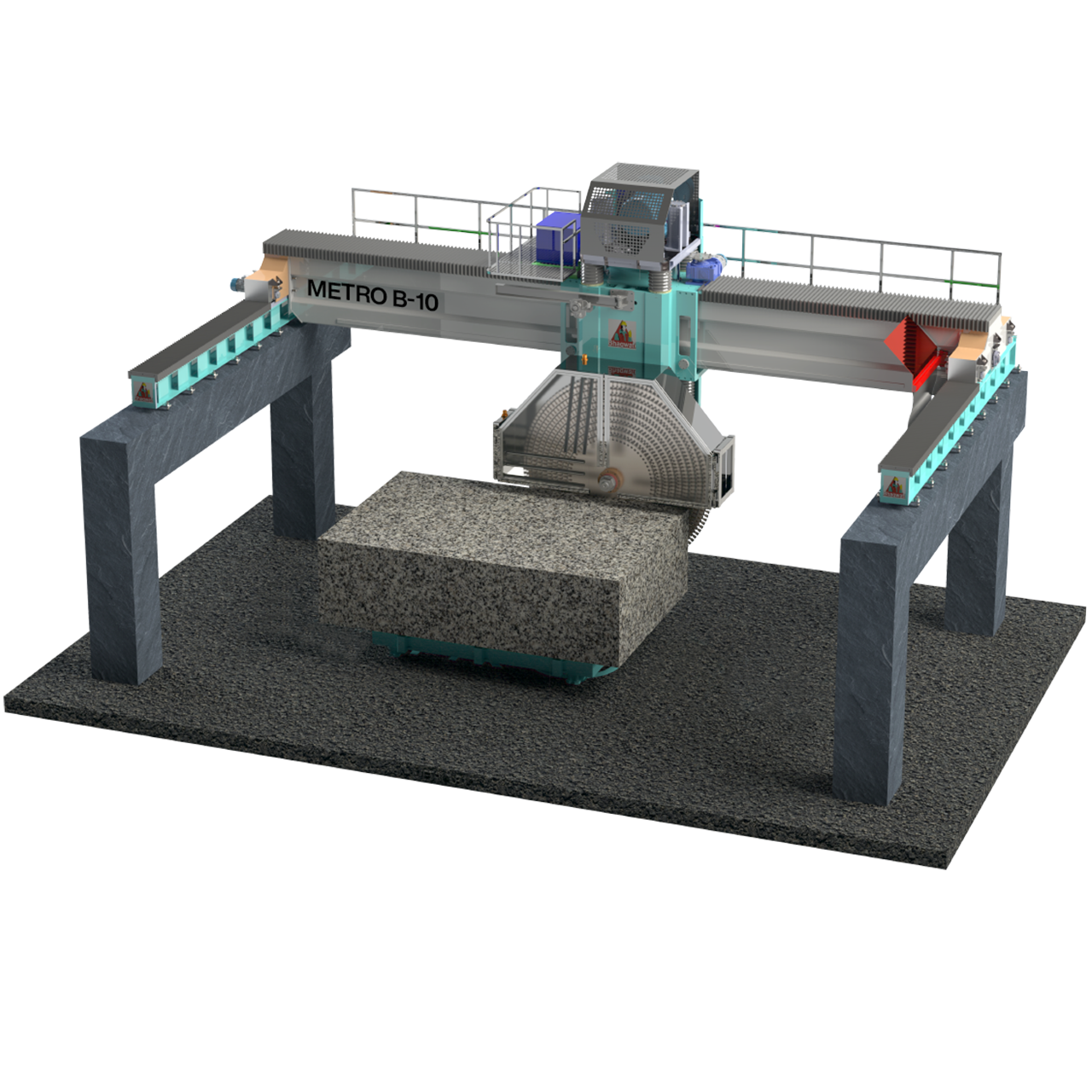

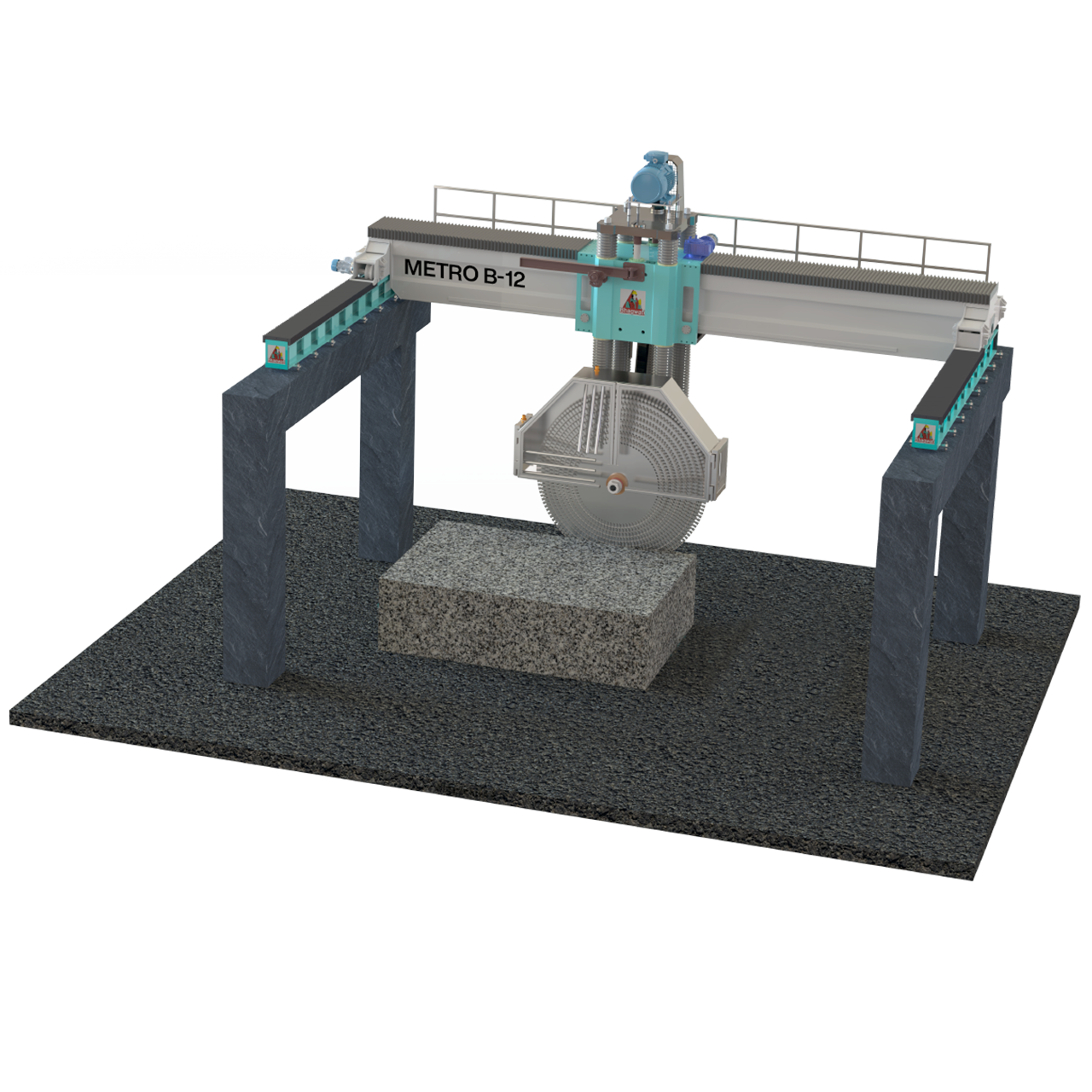

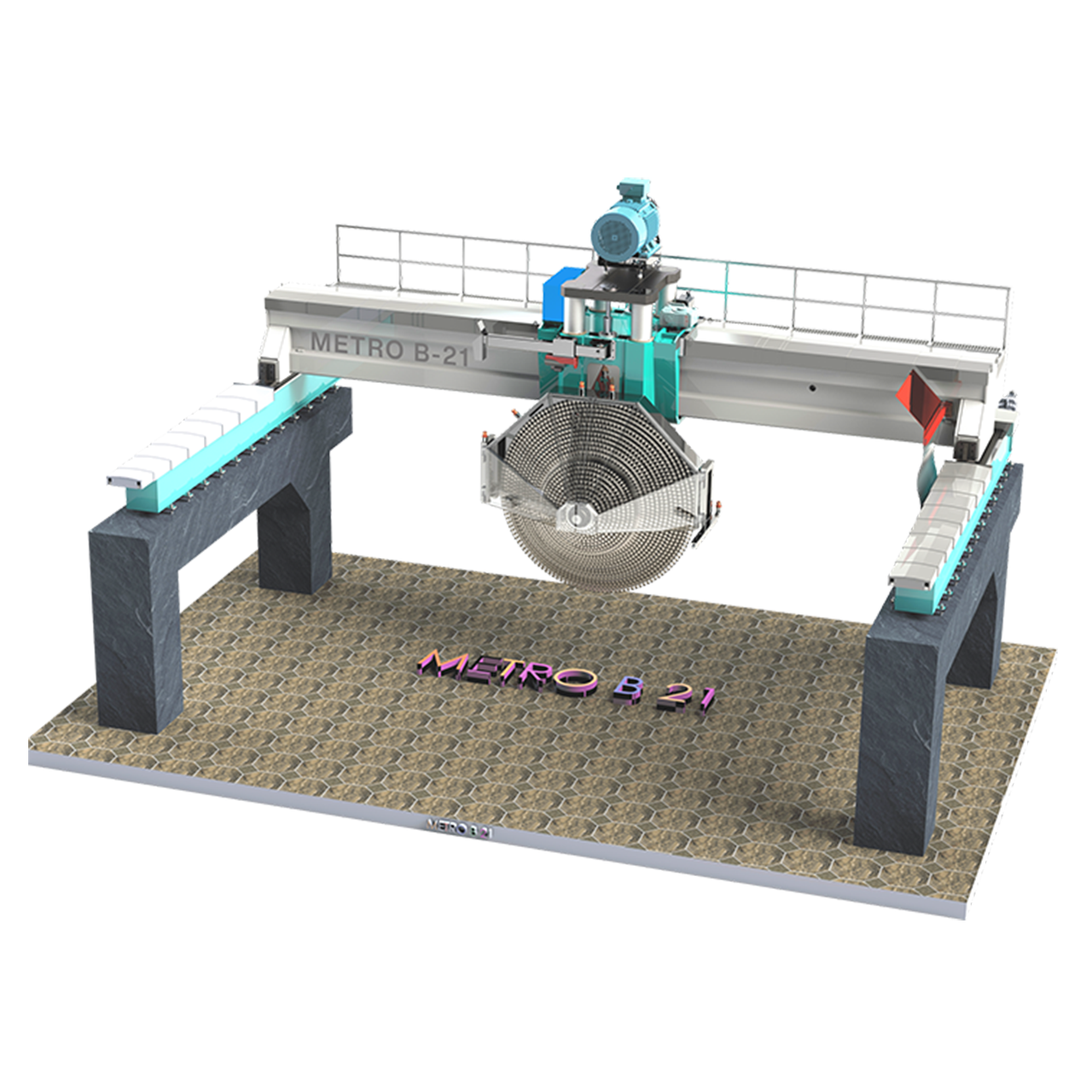

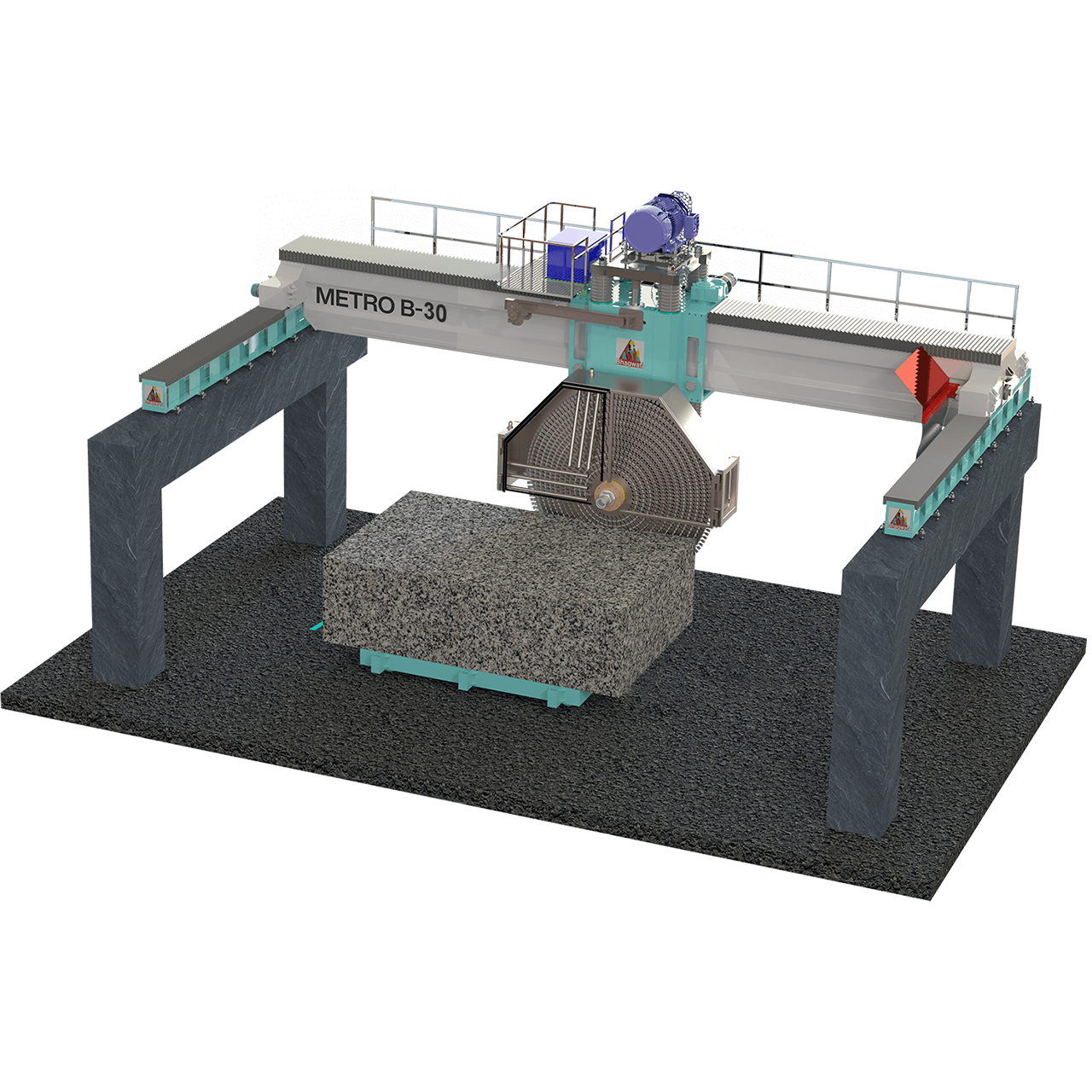

Overview of Metro-B10, Metro-B12, Metro-B13Pro, Metro-B14, Metro-B21, and Metro-B30

These all popular models of multicutter machines are commonly used in granite industries. Each of these machines offers unique features and capabilities that cater to different cutting needs. From smaller, more compact models like the Metro-B10 to larger, more powerful machines like the Metro-B21, there is a multi-cutter machine available according to the production capacity. In the following sections, we will delve deeper into the specifications and advantages of each of these machines to help you determine which one is best suited for your specific cutting requirements.

Benefits of using these SBMPL Multi-cutters

Multi-cutter machines offer a wide range of benefits for businesses in terms of efficiency, precision, and cost-effectiveness. By investing in a multicutter machine that is tailored to your cutting needs, you can streamline your production process, improve the quality of your cuts, and ultimately save time and money in the long run. These machines are versatile, reliable, and easy to operate, making them a valuable asset for any industry looking to enhance their cutting capabilities.

Increased Efficiency

Ability to cut multiple slabs in one pass

Multicutter machines have the ability to cut multiple slabs in one pass, which significantly increases efficiency in the production process. This means that you can save time and resources by completing multiple cutting tasks simultaneously, rather than having to switch between different machines or tools. Additionally, the precision and accuracy of multicutter machines ensure that each cut is consistent and high-quality, reducing the need for rework or adjustments. Overall, the increased efficiency provided by multi-cutter machines can help businesses meet deadlines, fulfill orders faster, and ultimately improve their bottom line.

Faster cutting speeds compared to manual methods

With the ability to cut through various materials quickly and accurately, businesses can increase their production output without sacrificing quality. This increased speed also allows for more flexibility in meeting customer demands and adapting to changing market conditions. Ultimately, the combination of efficiency and speed offered by multicutter machines makes them a valuable investment for businesses looking to streamline their operations and stay competitive in today's fast-paced market.

Reduces labor costs and time spent on cutting tasks

One of the key advantages of multi-cutter machines is their ability to reduce labor costs and the time spent on cutting tasks. By automating the cutting process, businesses can eliminate the need for manual labor and free up employees to focus on other important tasks. This not only increases efficiency but also helps to reduce the risk of human error, resulting in higher quality products. Additionally, the speed and precision of multi-cutter machines mean that tasks can be completed in a fraction of the time compared to traditional cutting methods, allowing businesses to meet tight deadlines and fulfill customer orders quickly. Overall, the reduction in labor costs and time spent on cutting tasks can lead to significant cost savings and improved productivity for businesses utilizing multicutter machines.

Precision Cutting

Consistent cuts with minimal errors

Minimal errors are essential in industries such as manufacturing, where precision is key to ensuring the quality of the final product. Multicutter machines excel in this aspect, as they are able to consistently produce accurate cuts with minimal errors. This level of precision is crucial in industries where even the smallest deviation can result in a faulty product or component. By utilizing multicutter machines for precision cutting tasks, businesses can ensure that their products meet the highest standards of quality and reliability. This not only enhances the reputation of the company, but also helps to build trust with customers who rely on consistent and precise products.

Ensures uniformity in finished products

Multicutter machines also help to ensure uniformity in finished products, as each cut is made with the same level of precision and accuracy. With multicutter machines, businesses can minimize variations in their products and maintain a high level of quality control throughout the production process. This ultimately leads to cost savings, as fewer defective products need to be discarded or reworked, resulting in higher efficiency and profitability for the company.

VERSATILITY

Can be used for a variety of materials such as granite

Multicutter machines also help to ensure uniformity in finished products, as each cut is made with the same level of precision and accuracy. With multicutter machines, businesses can minimize variations in their products and maintain a high level of quality control throughout the production process. This ultimately leads to cost savings, as fewer defective products need to be discarded or reworked, resulting in higher efficiency and profitability for the company.

Provides a high return on investment over time

One of the key benefits of investing in multicutter machines is the high return on investment they offer over time. While the initial cost of purchasing a multicutter machine may be significant, the long lifespan and low maintenance requirements of these machines mean that businesses can recoup their investment quickly. By reducing the need for frequent repairs and replacements, multicutter machines help businesses save money in the long run. Additionally, the increased efficiency and productivity provided by multicutter machines can lead to higher profits, further enhancing the return on investment for businesses.

In conclusion, the benefits of multicutter machines such as the Metro-B10, Metro-B12, Metro B-13 Pro, Metro B-14 Pro, Metro-B21, and Metro-B30 are clear. These machines offer significant cost savings through their long lifespan and low maintenance requirements, allowing businesses to recoup their investment quickly. Furthermore, the increased efficiency and productivity provided by multicutter machines can lead to higher profits, further enhancing the return on investment for businesses. Overall, investing in multicutter machines is a smart decision for businesses looking to improve their operations and save money in the long run.

Multi-cutter machines have revolutionized the manufacturing industry by streamlining processes and increasing output. By automating repetitive tasks and reducing human error. Additionally, the precision and accuracy of multicutter machines have led to higher quality output, ultimately enhancing the reputation and profitability of businesses. In conclusion, multi-cutter machines are an invaluable investment for any company trying to remain competitive in today's market because of their indisputable positive effects on production and profitability.