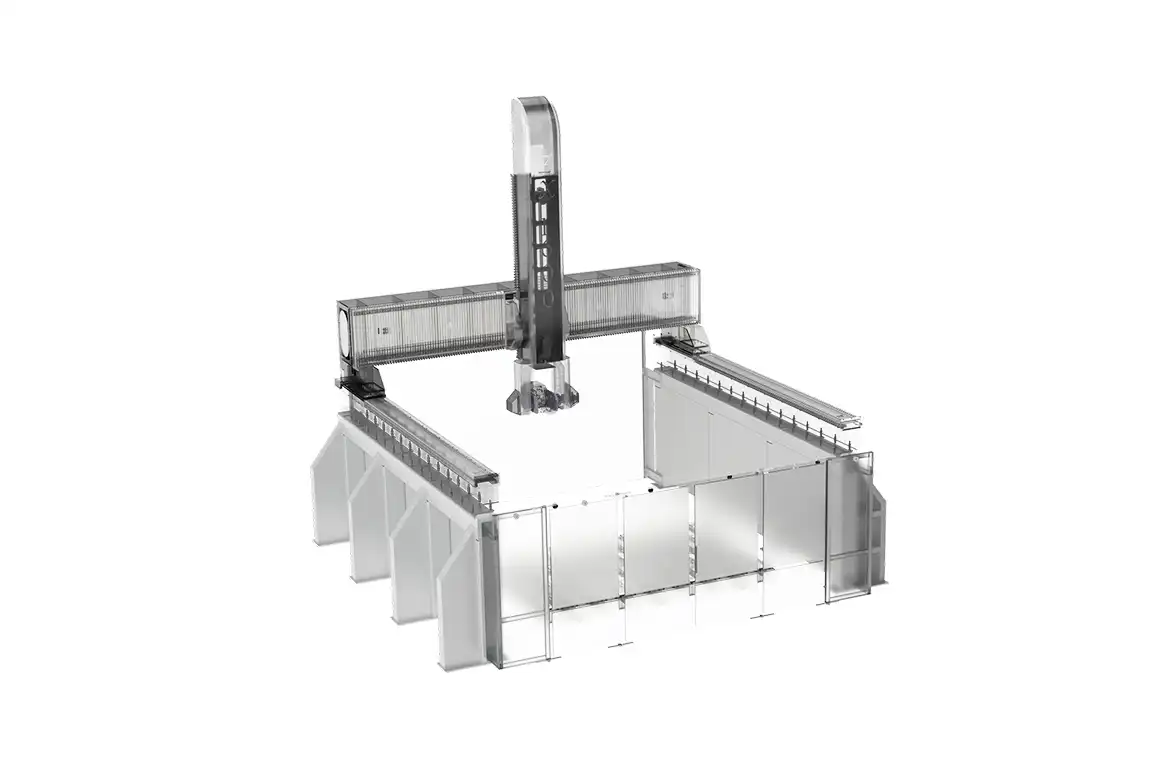

Monumill Zx-1600

CNC

Multifunctional

Signature Qualities

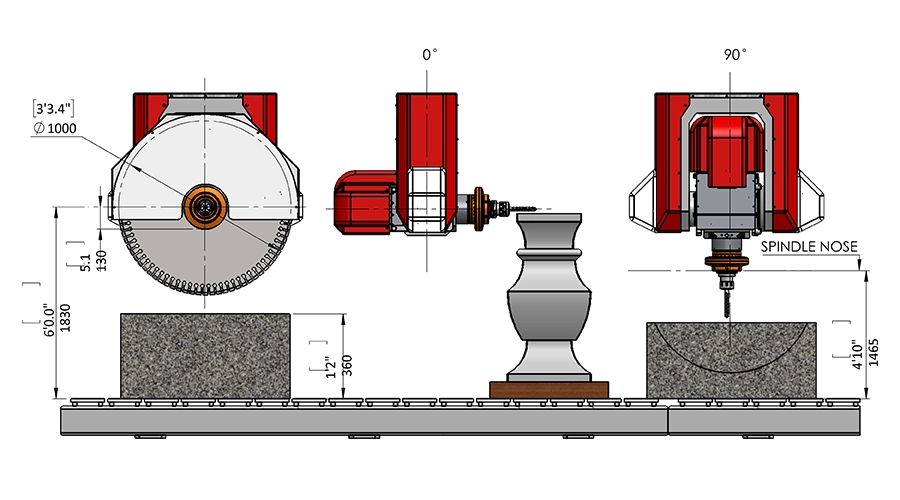

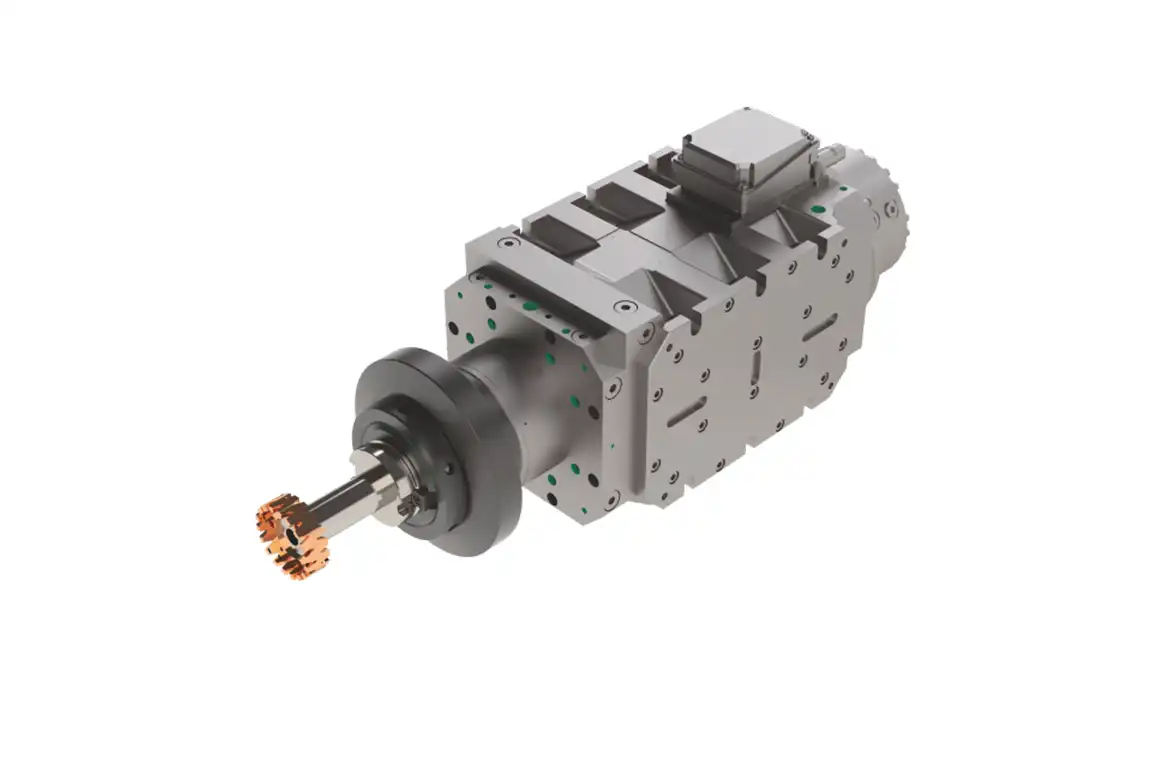

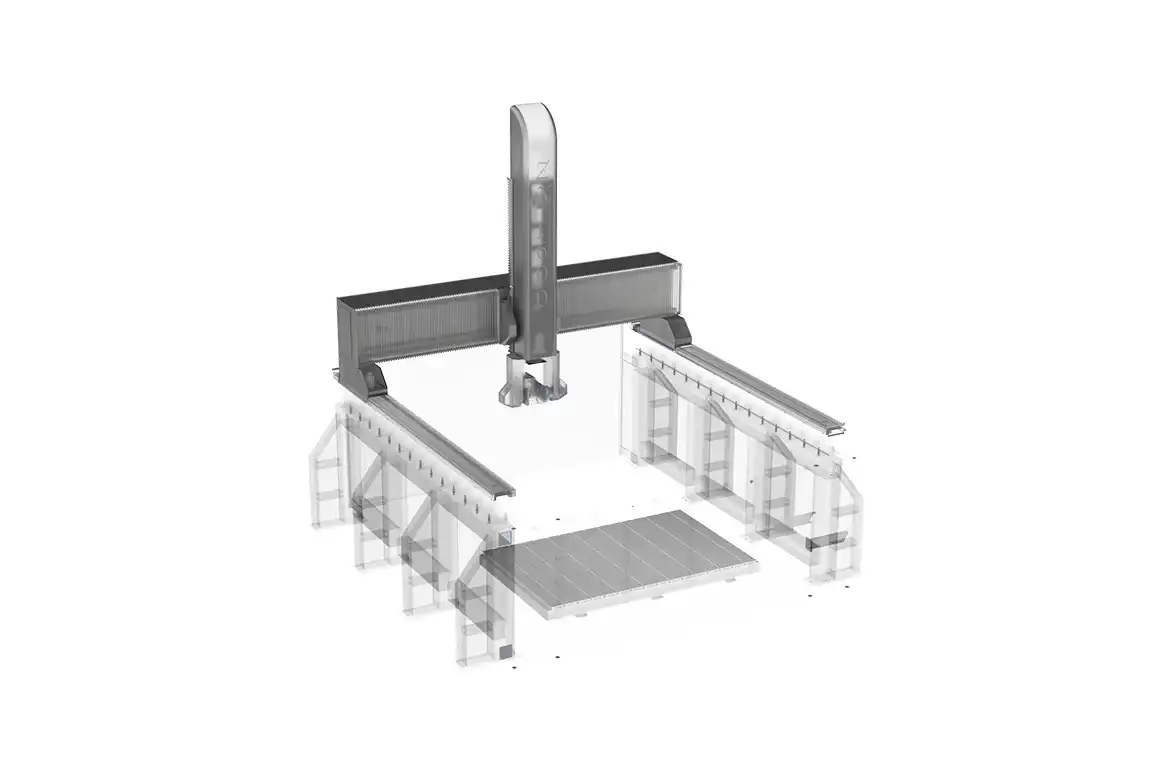

PRECISION REDEFINED BHAGWATI Zx-series machines are designed to be extremely versatile and powerful machining centers with high accuracy. Thanks to the steel bridge with a reinforced structure,axis movements generated by servo mofors coupled with ultra-high-precision gearboxes, includes X Axis Carriage (cross movement) which operates along the gantry, Y Axis - Overhead Gantry (Longitudinal Movement) which moves along end carriage on robust welded steel columns & horizontal beams. Z axis - Ram (Vertical Movement) which is mounted on the X axis carriage, featuring a pneumatic braking system for safe operation during voltage drops or power failures, C axis- Revolving Hood (Rotatory movement) securely attached to the ram, includes a precision gearbox for smooth 360° rotation, A axis- Spindle (Tilting Movement) features a tilting mechanism for accurate positioning and smooth adjustments across ifs designated range. it is possible to produce objects of various dimensions and shapes with exceptionally precise finishes.

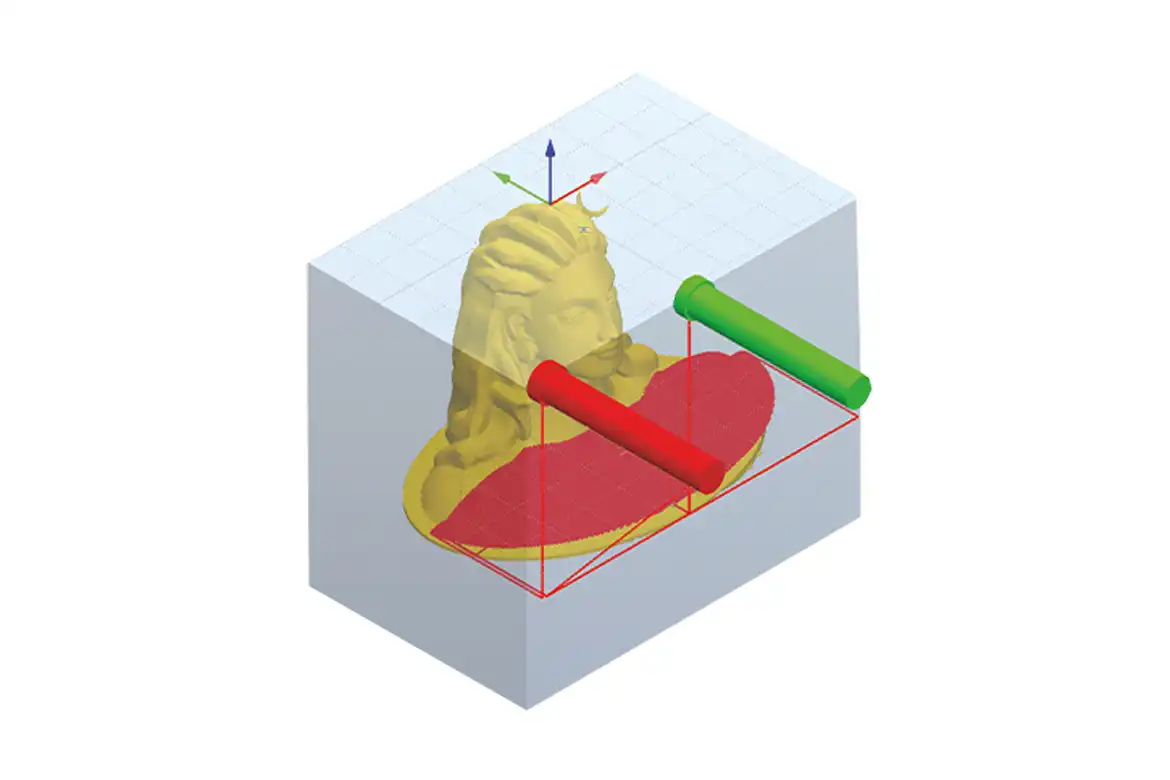

VERSATILE PRECISION These machines are equipped with inverter-controlled electrospindles featuring TOOLS with ISO 50 connections, capable of accommodating diamond blades with diameters ranging from 350 mm to 1000 mm, as well as various diamond tools. The system can also be configured with a lathe and a rotating platform, both incorporating an NC-controlled rotary axis, thereby increasing the interpolated axes from 5 to 6. With a wide range of accessories available in the catalog, the machine can be configured as a simple cutting fool or a machining center for complex processing tasks.

UNMATCHED VERSATILITY BHAGWATI Zx machines are ideal for customers seeking powerful and flexible solutions fo meet the increasingly complex challenges and projects of today’s market. All machines in the series are available with grease lubrication provided in the standard version.