SBMPL

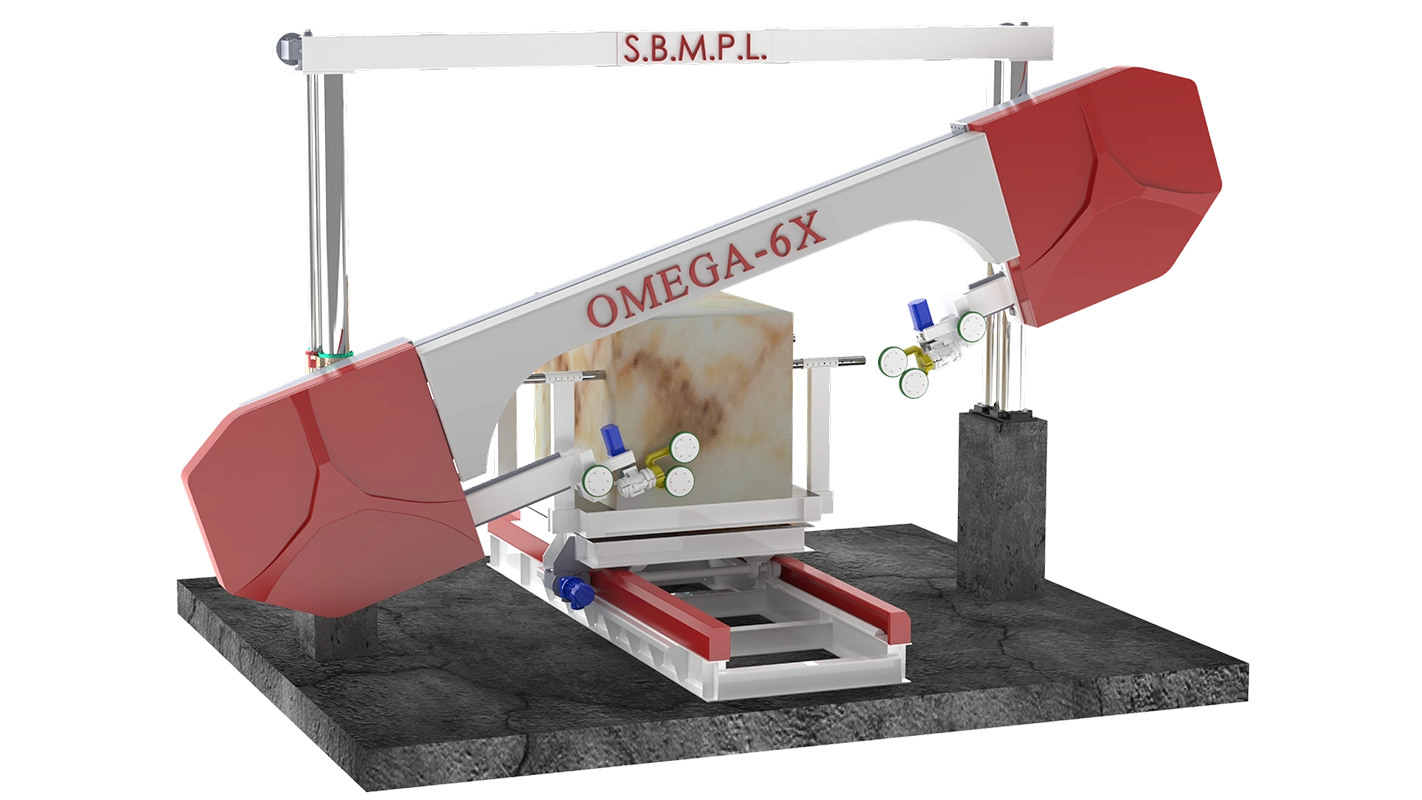

OMEGA-6x

Wire Profiling

Latest Innovative Model In Wire Profiling

Omega 6x -Innovative Wire Profiling Machine

The new Omega 6x wire profiling Machine is equipped with a CNC system, featuring 7 controlled axes for wire inclination of up to 22.5°.

BHAGWATI represents the latest innovative and advanced model in the historical range of BHAGWATI profiling machines. This version marks a significant evolution, as the diamond wire inclination can reach an angle of up to 22.5° (relative to the horizontal plane), allowing for the creation of a wider variety of shapes. It is the perfect machine for cutting two- and three-dimensional profiles from blocks of marble, granite, and ornamental stones, with dimensions of up to 2.0 meters in width and 1.5 meters in height. One of the key features of the BHAGWATI is its robust structure. The two groups of flywheels are connected by this structural element, which automatically adjusts their length using a micrometric telescopic system, depending on the wire angle and the diagonal distance between the main flywheels. This ensures that the guide wheels maintain a constant distance from the block, guaranteeing cutting precision in any configuration. The other six axes (block carriage shift, platform rotation, independent rotation of the two guide-wheel groups, and independent vertical displacement of the two flywheels) are controlled by brushless drives. The electronic tensioning system continuously monitors the wire tension, ensuring the fastest cutting speeds, even on the most complex profiles.

Structural Features

SIX Controlled Axes

A Computerized Numerial Control (CNC) system with six controlled axes, designed for cutting two and three dimensional profiles from marble, granite and ornamental stone blocks using diamond wire.

Special Protection

A well-designed structure with special protection ensures maximum cutting precision and extends the mechanical lifespan of all moving parts. The system's six axes including block carriage shift and rotation, two seperate wire guide-wheel rotations, and wire inclination (+-90 degrees) are powered by brushless drivers under computer control. This coordination enables precise axis movements to create the desired profile.

Easy Operations

Data input for the profile to be cut is simple, even for personnel without computer knowledge, thanks to our exclusive program. The linear speed of the diamond wire can be adjusted from 0 to 40 m/sec, depending on the type of stone, under the control of an inverter. The cutting speed varies from the set maximum based on the complexity of the cut. Wire tensioning is hydraulic.