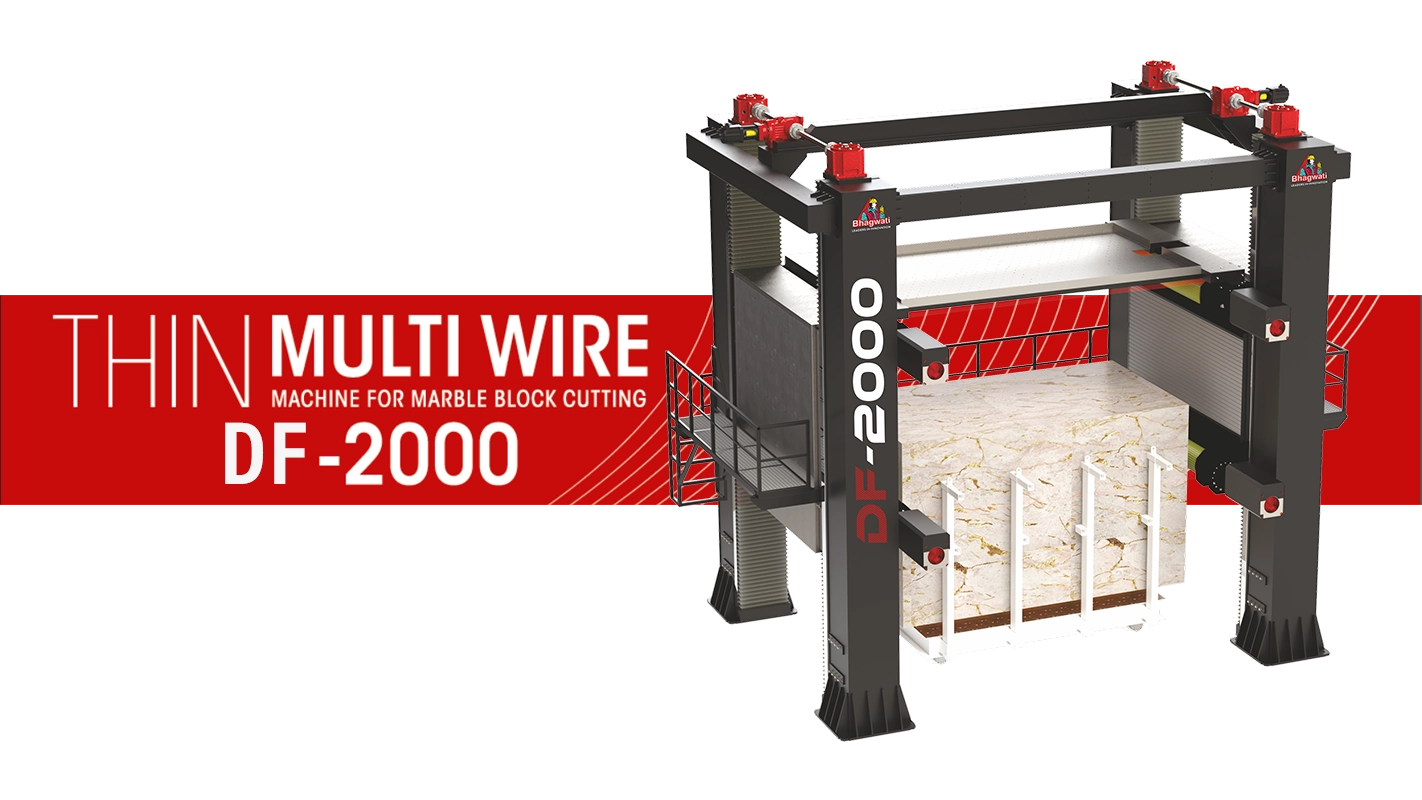

THIN MULTIWIRE D2000

Thin

Multiwire

INDIA's 1st Successfully Running Masterpiece

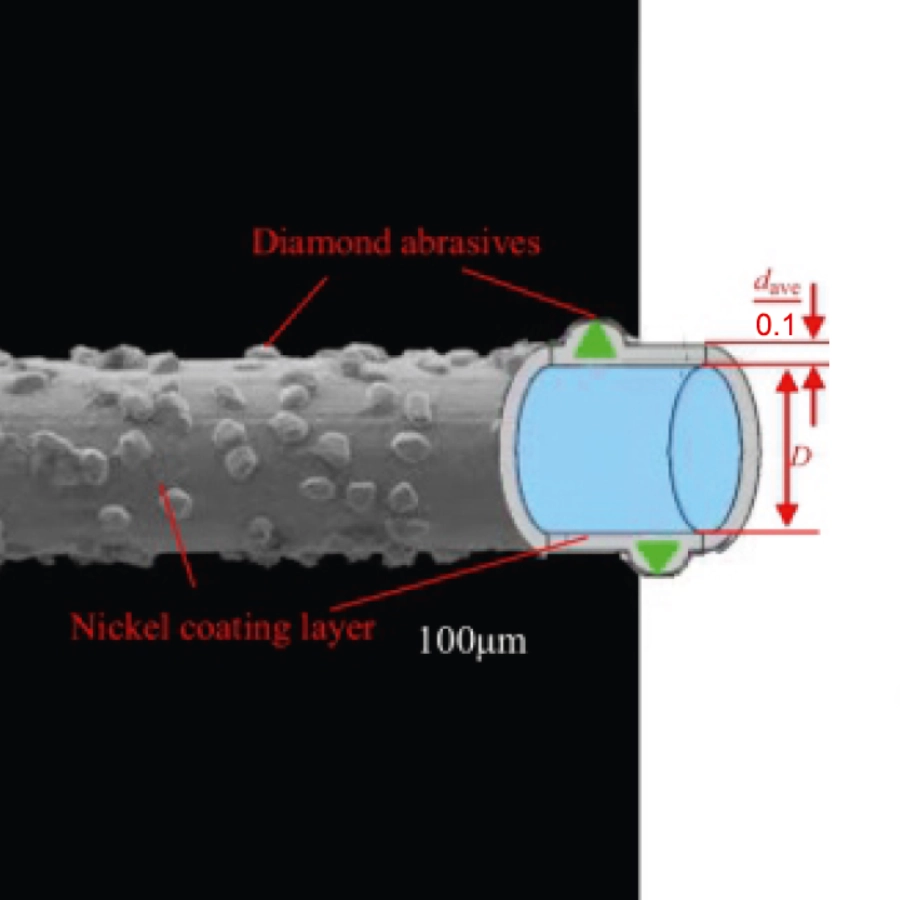

Diamond Electroplated Wire Cutting Technology

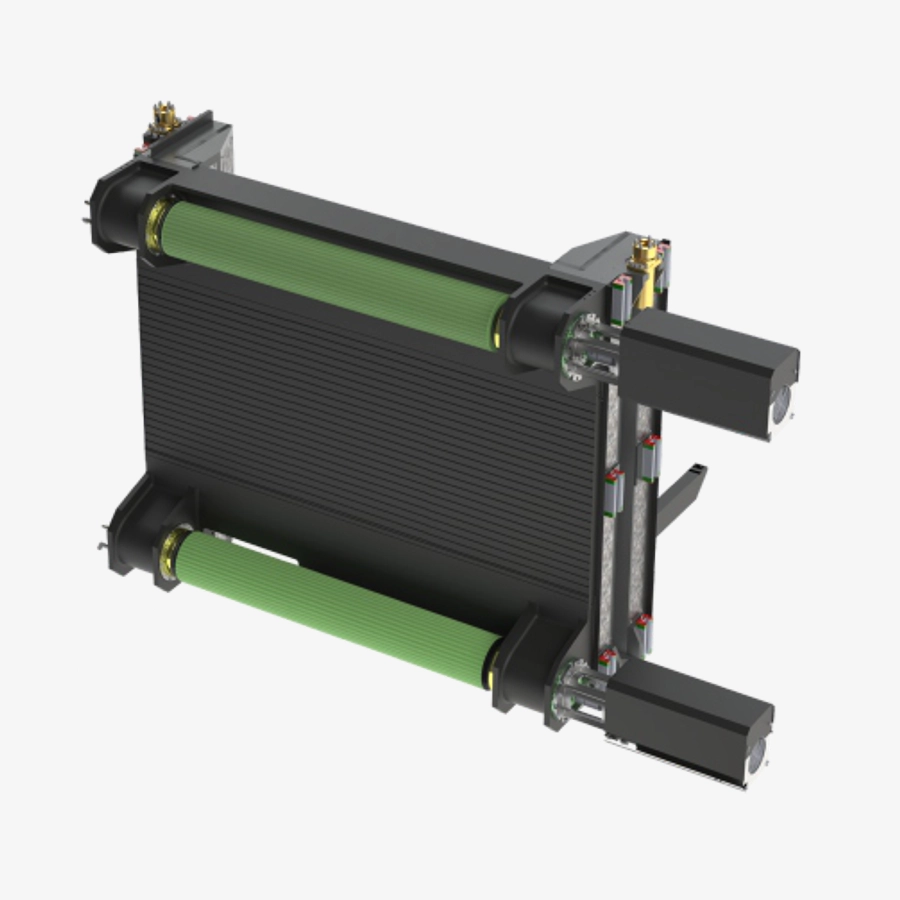

D Series thin multiwire block cutting machines by Shri Bhagwati Machines Pvt. Ltd. is an advanced stone-cutting solution designed for high-precision and efficient cutting of marble and granite blocks. Utilizing diamond electroplated wire technology, this machine ensures minimal material wastage, faster cutting speeds, and superior surface finish. Engineered for durability and performance, the D-2000 is ideal for quarries and processing units looking to enhance productivity while maintaining precision.

Structural Features

D Series Multiwire Machines

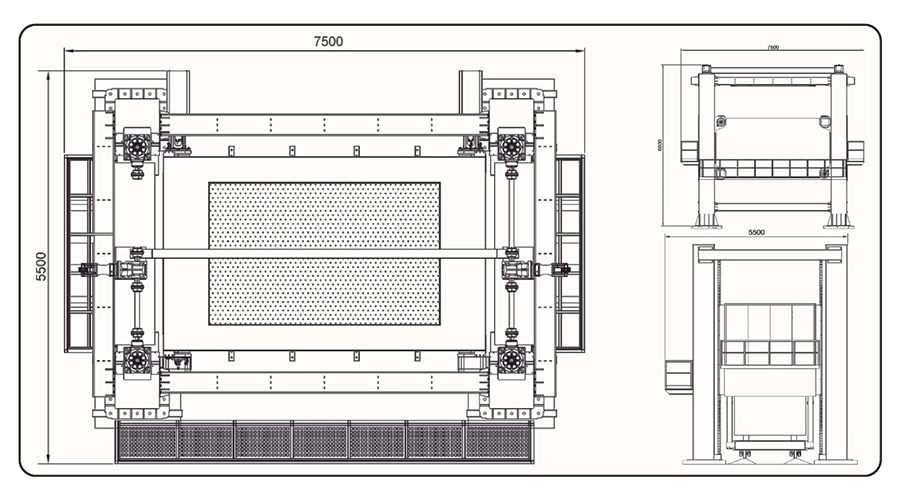

- The machine structure is made of heavy steel sheets on a box-shaped welded frame, while the main sliding roller frame is constructed from gray cast iron to ensure robust and stable.

- The machine features an automatic advance servo control system to ensure precise tensioning add execute the desired program.

- Comprehensive setup solutions are implemented for advanced servo systems, ensuring stable and reliable performance.

- The servo wire tensioning control system is designed to deliver precise and rapid adjustments, ensuring accurate wire tension for flawless cutting.

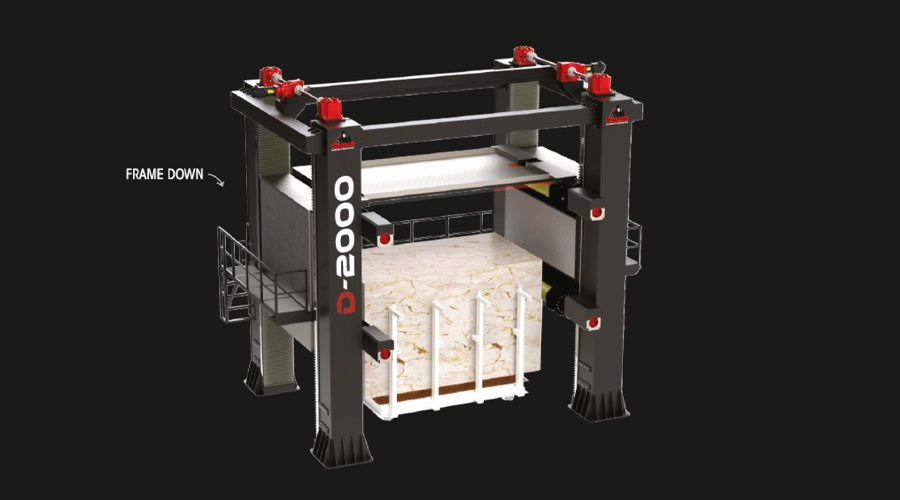

- The cutting feed features a two-axis-linked screw mechanism with servo-driven speed adjustment for precise downward feeding.

- The machine is capable of high-speed cutting with a wire speed of upto 25 m/s.

Working Principle

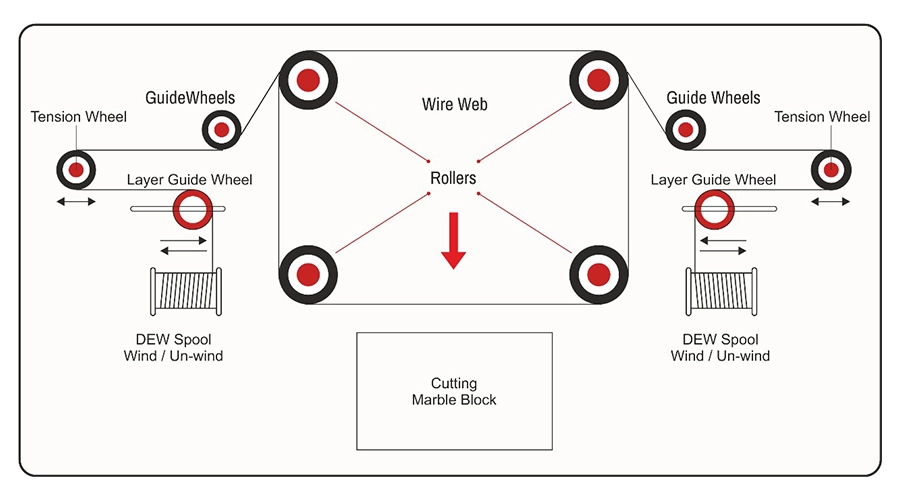

The stone multi-line cutting machine employs a rotor to drive a cutting line composed of diamond-beaded wire. Line wheels and guide wheels form a network around the main rollers, ensuring proper alignment and tension. This wire network enables simultaneous multi-wire cuts for efficient stone processing. The cutting line is guided back through additional guide wheels and stored in line reels for reuse. This system allows for precise, high-speed cutting of large stone blocks into managable pieces, making it ideal for stone quarries and offering enhanced productivity and accuracy.

The machine is equipped with four main rollers, each engraved with parellel grooves to securely hold the cutting line in place. Driven by a motor, these rollers operate alternately in forward and reverse directions. The alternating motion ensures continuous operation of the cutting line, improving efficiency. Longer forward operations times optimize the cutting process, while the reverse motion enhances line utilization. This design prevents line slippage and ensures consistent performance. Specifically designed for stone cutting, the machine maximizes productivity and extends the cutting line's lifespan.

During operation, the cutting line transitions from the wire to the clot wheel, gradually cutting into the material. The material is securely fixed on a workbench positioned perpendicular to the wire network. The wire network moves downward with consistent pressure and curved trajectory. As the cutting line grinds and cuts, the sections in contract with the wire are gradually removed. The cutting depth increases until the process is complete. This multi-line cutting machine delivers precision, efficiency, and adabtablity for various cutting operations.