SBMPL

Versawire

Multiwire

INDIA's 1st Successfully Running Masterpiece

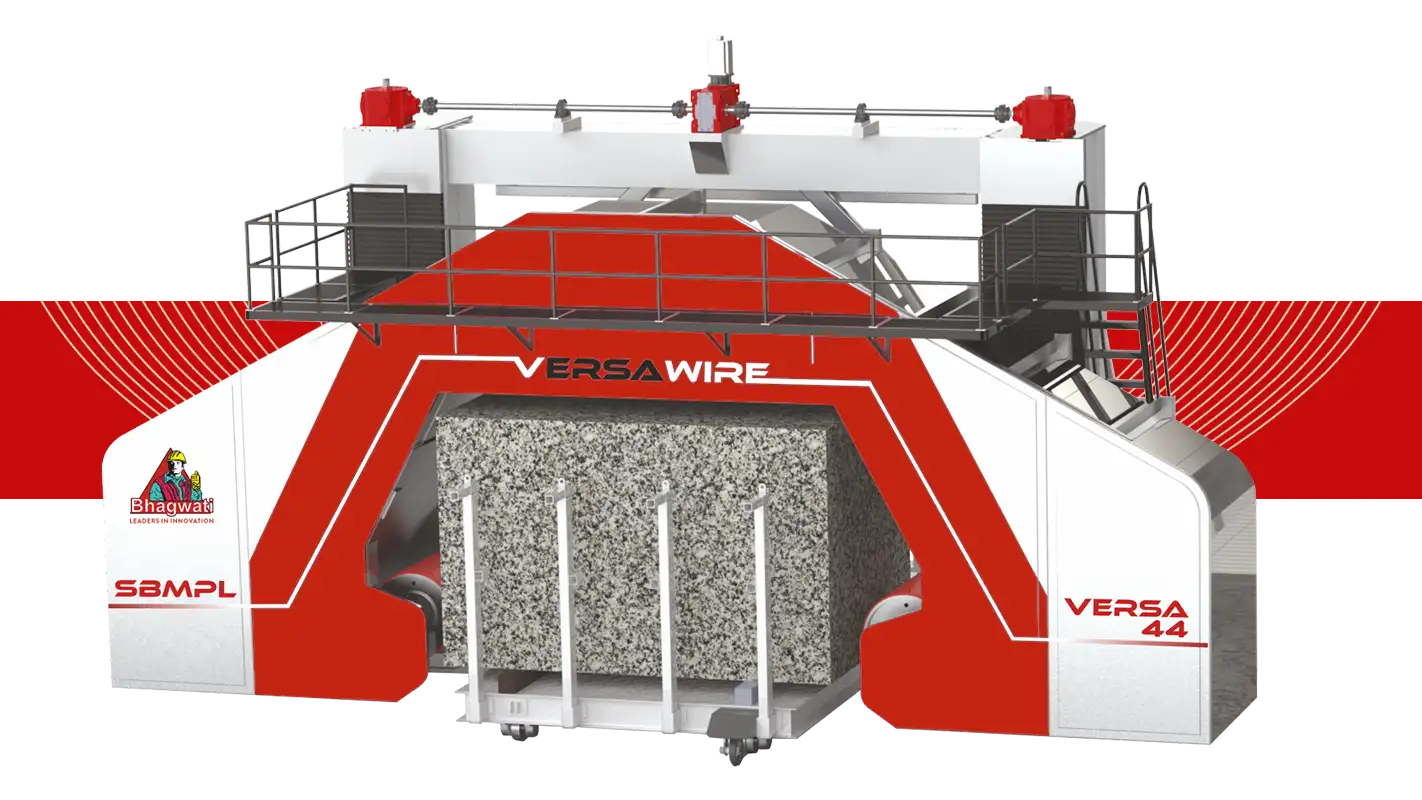

Versawire - Multiwire Block Cutting Machine

The VersaWire Multiwire Stone Block Cutting Machine by Shri Bhagwati Machines Pvt. Ltd. is a high-performance cutting solution designed for precision and efficiency. Equipped with advanced technology, it features multiple wires for simultaneous cutting, increasing productivity and reducing operational costs. The machine ensures smooth, accurate cuts on stone blocks, offering enhanced durability and reliability, making it ideal for large-scale stone processing operations.

Innovative triangular geometry: minimizes circuit bends and reduces wire vibrations.

Individual tensioning system: ensures stability, prevents breakage, and extends wire life.

Hydraulic control unit: adjusts pressure for optimal cutting.

Advanced bearings: durable and corrosion-resistant.

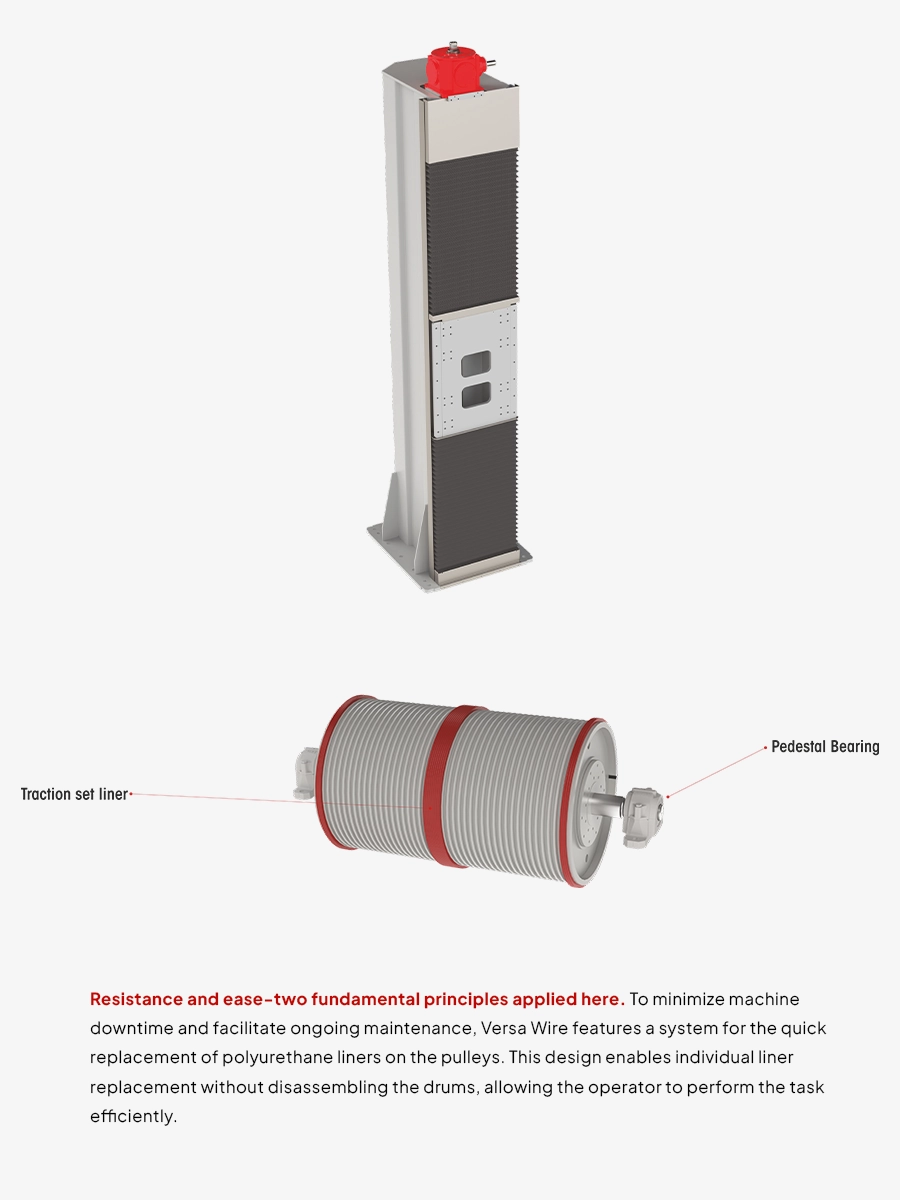

Quick change liners: Reduce downtime, no disassembly needed.

Efficient lubrication and cooling system: nine cleaning points extend wire life.

Stainless steel fairings: ensure durability and protect against dust and water during cutting.

Safe & ergonomic design: features walkways, safety sensors, and inspection points for easy maintanence.

Geater durability and power: Robust structure and high-quality materials ensure reliable performance.

Braking resistor: enables quick emergency stops to prevent accidents and losses.

Automatic lubrication: ensures proper machine conditioning with automatic lubrication.

Lock system: automated servo motor enables rapid rise in up to five minutes.

Guide rollers: larger diameter with fitted rubbers for enhanced durability and precision.

Models available by capacity: available in 4.3mm, 5.3mm, 6.3mm, and 7.3mm wires to meet plant needs.

Heat treatment: heat-treated shafts enhance resistance and reduce downtime.

Linear Guides: control up-and-down movements with precision.

Nearby technical assistance: skilled and professional team

Structural Features

Triangle Geometry & Tensioning

The Versa wire system features an innovative triangular geometry that minimizes circuit bends, reduces vibrations, and increases the durability of diamond wires. This design results in high-quality cuts and extends the equipment's lifespan. The same focus on durability is applied to its tension structure. To ensure each wire operates at the ideal tension and to prevent breakages, the Versa wire is equipped with an individual tensioning system featuring shielded bearing wheels and sensitive hydraulic cylinders, ensuring cutting stability.

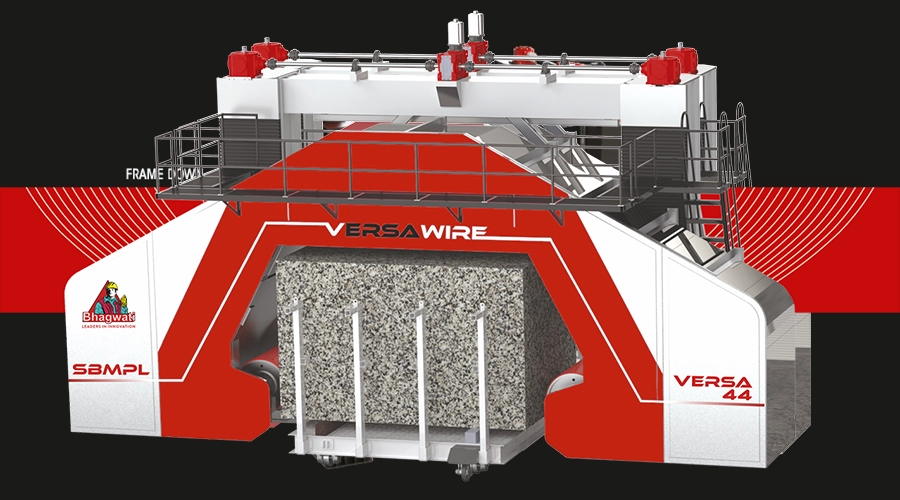

UP & DOWN Motion

The two columns are made of steel sheets on a box-shaped welded frame. The slide guides are coated with special, interchangeable steel surfaces on which the sliders move. The movement is achieved through a trapezoidal nut-spindle and spindle-nut mechanism. In machines with more than 44 wires, the upward and downward loads are assisted by two hydraulic cylinders. The entire guide system, including the nut-thread and trapezoidal thread spindle, is lubricated using a grease system and protected from environmental contamination by bellows. For machine models with more than 44 wires, we developed a fast lifting system equipped with a special servomotor, enabling the machine structure to be lifted in under or up to 5 minutes.

Drive Unit, Driven Unit, Axles & Rubber Interchangeability

Versa Wire incorporates several technical advancements to ensure high quality. Its drive unit features a 1,260 mm diameter drum made of carbon steel, driven by a motor that initiates the translation movement of the diamond wires. The unit is equipped with individual wheels, also 1,260 mm in diameter, made of machined and individually balanced aluminum alloys. This design compensates for cable length differences, reduces wear on polyurethane liners, and enhances equipment durability.